|

|

Post by jennifer on Sept 24, 2019 14:52:56 GMT

I take a gander back into the 3D printing world after a 2 year hiatus, and wow, this printer is amazing! How much does the resin cost compared to PLA filament? it prints at 0.05 layer height? They sure put out some nice looking minis! Only $289 too! www.monoprice.com/product?p_id=30994 |

|

drl2

Tool Gatherer

Posts: 57

|

Post by drl2 on Sept 24, 2019 15:13:46 GMT

I've heard pretty mixed reviews of the Monoprice. You can sometimes get an Anycubic Photon on sale for around that amount, which comes with a huge support community. (For the record my Photon has been kind of a mess, but that's almost entirely due to user error  . Its results are amazing when I haven't broken anything  For $400 I ended up getting an Epax X1 also, which is not only faster than the Photon but so far has proved much more resistant to my bumbling. Between the two I've printed 400+ minis over the last few months. The biggest downside is that the many free but not-so-detailed monster STLs on Thingiverse start to look disappointing when their textures don't do a good job of showing off the printer's capabilities. (That, and my painting skills aren't necessarily up to doing justice to my prints...) |

|

|

|

Post by Meph on Sept 27, 2019 21:51:06 GMT

|

|

|

|

Post by wilmanric on Oct 1, 2019 14:43:05 GMT

Meph Can you please give us an honest assessment of the mess/chemicals/smells associated with resin printing? I'm interested, but I'm getting mixed messages from what I read online. I alternate between, "that's not too bad" to "OMG it sounds like a superfund site."

|

|

|

|

Post by erho on Oct 1, 2019 15:18:31 GMT

Elegoo Mars 2 seems to be a good response from youtube crafters,

Elegoo Mars 2 on Amazon

I'll be ordering one within the month unless I come across a known issue with the model, but I'll read intot his one you have before I make the plunge!

Thank you

|

|

|

|

Post by tauster on Oct 1, 2019 20:07:26 GMT

Elegoo Mars 2 seems to be a good response from youtube crafters,

Elegoo Mars 2 on Amazon

I'll be ordering one within the month unless I come across a known issue with the model, but I'll read intot his one you have before I make the plunge!

Thank you

I'd be interested in your experiences with the Mars 2.

These things are becoming cheap enough for me to make getting into 3D printing more and more enticing. Time is the only major reason that keeps me from going down this rabbit hole.  |

|

|

|

Post by Meph on Oct 1, 2019 20:11:32 GMT

Elegoo Mars and Anycubic Photon are about on par with each other in terms of quality and price. Photon has been around longer and has a larger community but you wont go wrong with either.

My link and your link are the same price but the Anycubic comes with Resin and an addition FEP film which the Elegoo Mars doesn't.

|

|

|

|

Post by Meph on Oct 1, 2019 20:23:22 GMT

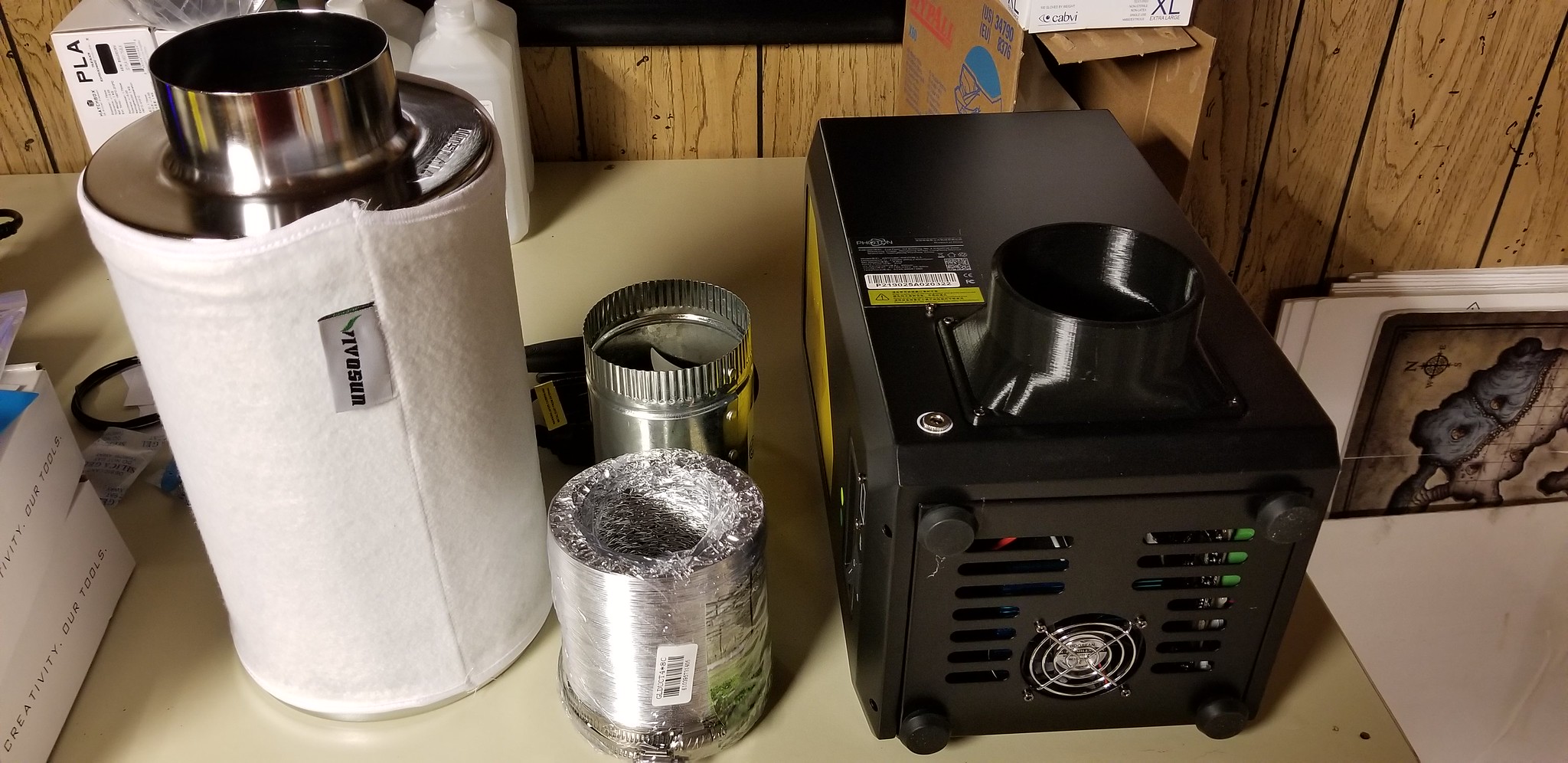

Meph Can you please give us an honest assessment of the mess/chemicals/smells associated with resin printing? I'm interested, but I'm getting mixed messages from what I read online. I alternate between, "that's not too bad" to "OMG it sounds like a superfund site." So the reason responses are all over the board is because of resin brands/colors and air filtration. Resin stinks. Some is worse than other. Some people are affected worse than others. Anycubic Green is what comes with it and it stinks pretty bad. I have no windows for easy access so I am using a carbon filtration system for mine. There is a small fan in the chamber of the machine that blows air down into the bottom and there is a vent in the back that air filters out. It does nothing other than kick resin odors into your house. I disconnected the fan internally and then removed the vent plate on the back. I 3D printed a new vent plate that converts to a 4" dryer vent. I run an inline 4" vent that blows air from the inside of the machine to a growhouse carbon filter. They are reversible so if you are blowing fumes into it, the outer sleeve actually goes inside. Using this I have no fumes at all when printing. The only time I get any smell is when I open it to remove a print and that is minor. As for types of resin I am experimenting. Anycubic Green prints really nice but stinks. Elegoo Grey has a low odor but I am less happy with my prints. I think I prefer translucent resins. I am using Elegoo Grey right now and with my setup you cannot smell it at all.   [ |

|

|

|

Post by Meph on Oct 1, 2019 20:24:28 GMT

Oh and that bottom fan blows in to keep the pc board cool. I left that as is. The inline fan has enough suction that no air escapes out the bottom.

|

|

|

|

Post by wilmanric on Oct 2, 2019 14:13:46 GMT

Oh and that bottom fan blows in to keep the pc board cool. I left that as is. The inline fan has enough suction that no air escapes out the bottom. So, there's quite a bit more setup beforehand. I appreciate the info. Thank you.

What about the prints? Is it true you have to wash them 3x in alcohol baths and then set them outside in the sun to "fully cure"?

|

|

|

|

Post by erho on Oct 2, 2019 16:20:53 GMT

Stink and a curing process. Did not know about this! good to know.

As far as the stink, curing step and grow house carbon filters remind me of local "medicinal" grow operation.

Probably run both at the same time in the same room and maximize profits for paint funds? ;-)

|

|

|

|

Post by wilmanric on Oct 2, 2019 17:05:17 GMT

Oh and that bottom fan blows in to keep the pc board cool. I left that as is. The inline fan has enough suction that no air escapes out the bottom. I think I might be able to vent out a window -- To recap -- you use the built-in fan to blow air through a 3D printed "adapter" connected to dryer hose -- this could be vented out a window, right? |

|

drl2

Tool Gatherer

Posts: 57

|

Post by drl2 on Oct 2, 2019 17:59:32 GMT

Oh and that bottom fan blows in to keep the pc board cool. I left that as is. The inline fan has enough suction that no air escapes out the bottom. So, there's quite a bit more setup beforehand. I appreciate the info. Thank you.

What about the prints? Is it true you have to wash them 3x in alcohol baths and then set them outside in the sun to "fully cure"?

For some reason I don't notice the smells of any of the resins I've tried except for Siraya Blu. But I don't want the fumes in the house so my printers are in the garage and I open the door and/or a window when I'm working with them just to be safe. This way there are no special air circulation considerations... though I likely won't be able to print in the dead of winter because low temps adversely impact resin's reactions and it gets pretty cold out there. There are a few different schools of thought on washing. - I use 91% isopropyl alcohol because I can get it locally fairly cheaply. I have two vats of it; new prints get dipped into the (usually dirtier) first vat for usually 3 or so minutes, and I gently shake or stir to agitate the liquid while it's soaking. Then I pull out each piece, dip a soft bristled toothbrush into the alcohol, and use it to scrub the items. Last, I put them into the 2nd (cleaner) vat for another few minutes of soaking + agitation.

- Lots of people buy cheap ultrasonic jewelry cleaners and just drop the items into those on a 15 minute or so timer.

- Some folks in placed where the alcohol solution is more expensive or harder to find (or they just don't like the alcohol) have reported success in using de-greasing liquids ("Mean Green" I think is the brand name I've heard mentioned most) with either of the methods above.

If you do use the alcohol, make sure your items are thoroughly dry before you begin the curing process - remnants of the alcohol on the surface can make it white & cloudy.

- For curing, I usually just put the pieces out in direct sunlight for highly scientifically measured cure time of "a little while". Sometimes 15 or 20 minutes is plenty, but I've left them out for upwards of two hours by accident (which resulted in items which are still solid but probably brittle). Usually probably 30 min or so, which in itself might be overkill. With clear resin most of the time I don't even turn them, but for opaque resins I usually rotate them a couple of times to make sure all sides are exposed. Some people like to drop their prints into clear glass jars of water for this process to evenly diffuse the light, though I haven't noticed any curing issues that made me want to try that method, though

- For those times when it's cloudy out or it's late and I don't want to wait until the next day for the cure, I built a curing chamber for something like $30 US. It consists of one of those fold-up cardboard office storage boxes lined with shiny-side-up aluminum foil, with a 6'-ish self-adhesive strand of UV LED lights wrapped around the inside. Into that I put a cheap solar-powered rotating jewelry display thing. I sit the prints on the rotating platform, put the cover on (making sure to never look at the lights when they're on) and plug in the LEDs. The items rotate in a bath of UV light. I usually leave these in longer than the sun-curing time, but again it mostly amounts to "a little while".

For me the biggest downside to resin printing is the difficulty in remembering not to touch the printer and things around it while wearing gloves wet with resin. Everything near the printer is slightly sticky

|

|

|

|

Post by tauster on Oct 2, 2019 19:47:48 GMT

- For curing, I usually just put the pieces out in direct sunlight for highly scientifically measured cure time of "a little while". Sometimes 15 or 20 minutes is plenty, but I've left them out for upwards of two hours by accident (which resulted in items which are still solid but probably brittle). Usually probably 30 min or so, which in itself might be overkill. With clear resin most of the time I don't even turn them, but for opaque resins I usually rotate them a couple of times to make sure all sides are exposed. Some people like to drop their prints into clear glass jars of water for this process to evenly diffuse the light, though I haven't noticed any curing issues that made me want to try that method, though

Does that mean that those UV resins do get brittle over time, when exposed to sunlight?

What happens when I have them standing around in my room where the sun can reach them? I know that UV light gets filtered out a bit through window glass (afaik at least), but still, over time...?

|

|

|

|

Post by Meph on Oct 2, 2019 19:48:35 GMT

Oh and that bottom fan blows in to keep the pc board cool. I left that as is. The inline fan has enough suction that no air escapes out the bottom. I think I might be able to vent out a window -- To recap -- you use the built-in fan to blow air through a 3D printed "adapter" connected to dryer hose -- this could be vented out a window, right? Yes you can vent it right out the window. The only window close by for me sits directly under my son's bedroom window and AC unit. Din't want to vent it out and then have it sucked right into his room. |

|

drl2

Tool Gatherer

Posts: 57

|

Post by drl2 on Oct 3, 2019 2:15:39 GMT

- For curing, I usually just put the pieces out in direct sunlight for highly scientifically measured cure time of "a little while". Sometimes 15 or 20 minutes is plenty, but I've left them out for upwards of two hours by accident (which resulted in items which are still solid but probably brittle). Usually probably 30 min or so, which in itself might be overkill. With clear resin most of the time I don't even turn them, but for opaque resins I usually rotate them a couple of times to make sure all sides are exposed. Some people like to drop their prints into clear glass jars of water for this process to evenly diffuse the light, though I haven't noticed any curing issues that made me want to try that method, though

Does that mean that those UV resins do get brittle over time, when exposed to sunlight?

What happens when I have them standing around in my room where the sun can reach them? I know that UV light gets filtered out a bit through window glass (afaik at least), but still, over time...?

Clear resins tend to get more opaque if they're cured for a long time, and I've left some out in ambient but not direct sunlight for a few days before priming them and not had them darken noticeably. Once you've primed and/or painted them (or treated them with a clear coat that specifically says it's UV resistant - I know Krylon makes one) the curing process will stop.

|

|

|

|

Post by tauster on Oct 3, 2019 7:25:12 GMT

Oh... I somehow pverlooked that most pieces will probably be painted after printing them.  |

|

|

|

Post by curufin on Oct 3, 2019 14:27:30 GMT

|

|

|

|

Post by sgtslag on Oct 3, 2019 19:00:07 GMT

I agree, a resin printer is the only way to go for printing mini's. What has stalled me, aside from the learning curves, is the price of resins. How many mini's, for example, can you print from a bottle of resin, and how much is the resin cost, per mini? Printing terrain is something I would use an FDM printer for. Cheers!

|

|

|

|

Post by Meph on Oct 3, 2019 20:04:34 GMT

I haven't calculated the exact costs per mini but I can say I have printed probably 200 minis, maybe more, from the 250ml Green, 1L Green, and about 500ml of Grey so far. Each Liter is $45 so figure about $78.75 in resin costs so far. So if we figure a low value of 200 minis printed them they cost me $2.53 each. Price wise it's still cheaper than almost all minis with the exception of maybe some smaller Bones minis.

The real benefit though is that I print what I want/need, when I need it. I am working on a small kobold tribe right now. I will get some pics up in a bit for you of what I have so far. If you forget the upfront cost of the printer, you will never buy commercial minis cheaper and even the printer cost will be offset in the first year if you buy nearly as much as I print.

|

|